Description

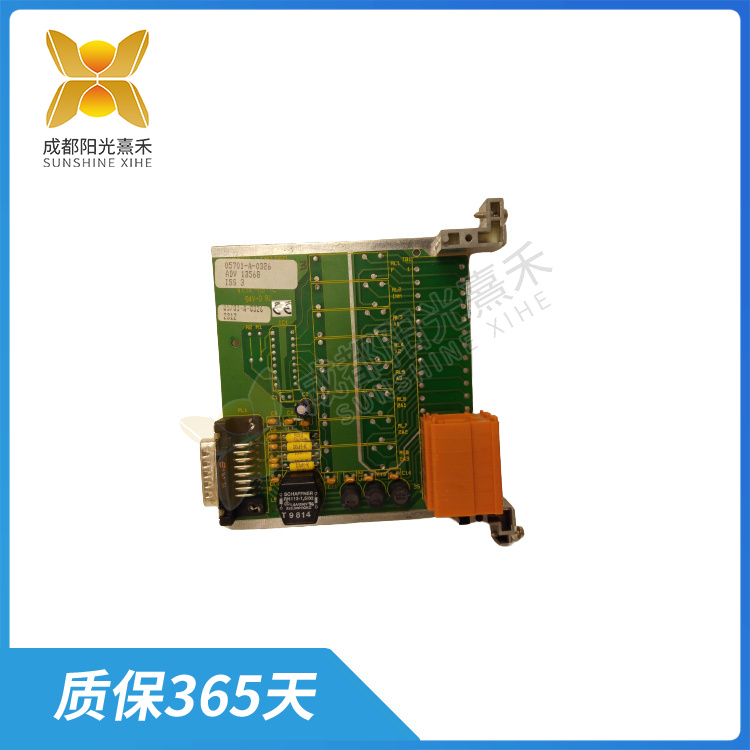

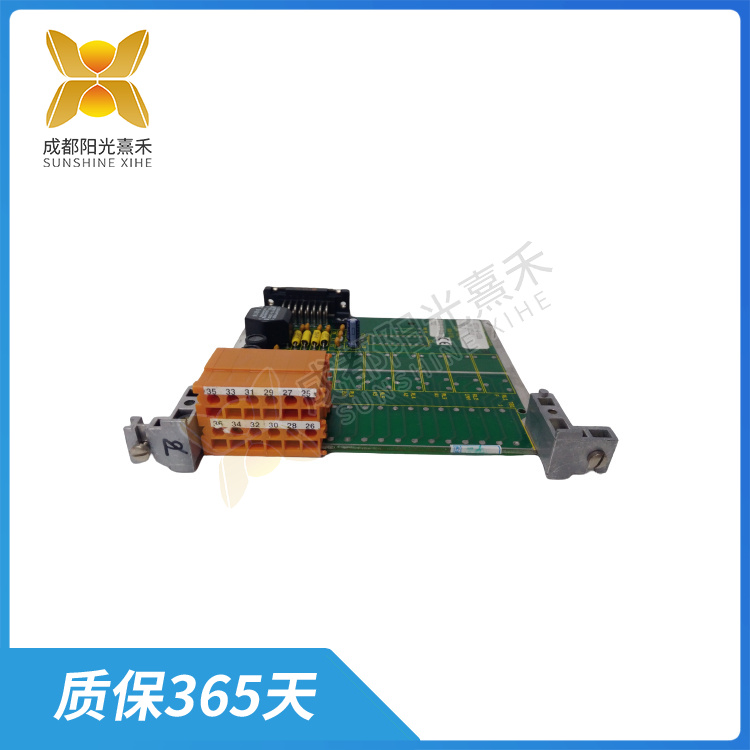

05701-A-0326 对机械臂的运动加速度进行控制,以避免因过快或过慢引起的冲击或振动

05701-A-0326工业机器人控制器是工业机器人系统的核心组成部分,其主要功能包括:

控制机械臂末端执行器的运动位置:通过控制电机和传动装置,实现对机械臂末端执行器位置的精确控制,包括经过的点和移动路径等。

控制机械臂的运动姿态:根据实际需要,对机械臂的各个关节进行运动姿态的控制,实现各种复杂动作的精确再现。

控制运动速度:根据输入的指令或传感器反馈的数据,对机械臂的运动速度进行实时控制,确保其按照设定的轨迹和速度运动。

控制运动加速度:对机械臂的运动加速度进行控制,以避免因过快或过慢引起的冲击或振动,提高机械臂运动的稳定性和精确度。

控制机械臂中各动力关节的输出转矩:根据实际需要,对机械臂各关节的输出转矩进行精确控制,实现各种负载下的稳定运动。

具备操作方便的人机交互功能:通过控制器的人机交互界面,操作人员可以方便地输入指令、查看状态和调整参数,提高工作效率和便捷性。

使机器人对外部环境有检测和感觉功能:通过传感器和算法,机器人控制器可以实现对外部环境的感知和检测,根据环境变化调整运动状态和策略。

安全保护功能:机器人控制器应具备故障诊断和保护功能,防止因意外情况导致的设备损坏和人员伤亡。

可编程性:机器人控制器应支持多种编程语言和开发环境,方便用户进行控制逻辑和算法的定制和扩展。

通信功能:机器人控制器应支持多种通信协议和接口,实现与其他设备或系统的互联互通和信息交换。

总之,05701-A-0326 工业机器人控制器是实现机器人自动化控制的核心部分,具备多种功能特点,可以广泛应用于各种工业自动化场景。如需更多相关信息,建议咨询机器人技术专家或查阅相关行业报告。

05701-A-0326 对机械臂的运动加速度进行控制,以避免因过快或过慢引起的冲击或振动

05701-A-0326 Industrial robot controller is the core component of industrial robot system, its main functions include:

Control the moving position of the end actuator of the manipulator arm: by controlling the motor and the transmission device, the position of the end actuator of the manipulator arm is accurately controlled, including the passing point and the moving path.

Control the motion posture of the robot arm: according to the actual needs, the motion posture of each joint of the robot arm is controlled to achieve the accurate reproduction of various complex actions.

Control motion speed: According to the input instructions or sensor feedback data, the movement speed of the robot arm is controlled in real time to ensure that it moves according to the set trajectory and speed.

Control motion acceleration: The motion acceleration of the mechanical arm is controlled to avoid impact or vibration caused by too fast or too slow, and to improve the stability and accuracy of the motion of the mechanical arm.

Control the output torque of each power joint in the mechanical arm: according to the actual needs, the output torque of each joint of the mechanical arm is precisely controlled to achieve stable motion under various loads.

With convenient man-machine interaction function: Through the man-machine interaction interface of the controller, the operator can easily input instructions, view the status and adjust parameters, improve work efficiency and convenience.

Enable the robot to detect and sense the external environment: through sensors and algorithms, the robot controller can realize the perception and detection of the external environment, and adjust the motion state and strategy according to environmental changes.

Safety protection function: The robot controller should have fault diagnosis and protection function to prevent equipment damage and casualties caused by accidents.

Programmability: The robot controller should support a variety of programming languages and development environments, so that users can customize and extend the control logic and algorithms.

Communication function: The robot controller should support a variety of communication protocols and interfaces to achieve interconnection and information exchange with other devices or systems.

In short, 05701-A-0326 industrial robot controller is the core part of robot automation control, with a variety of functional characteristics, can be widely used in a variety of industrial automation scenarios. For more information, it is recommended to consult a robotics expert or consult relevant industry reports.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: