Description

1svr040000r1700 75-T651的硬度(HB15)的硬度

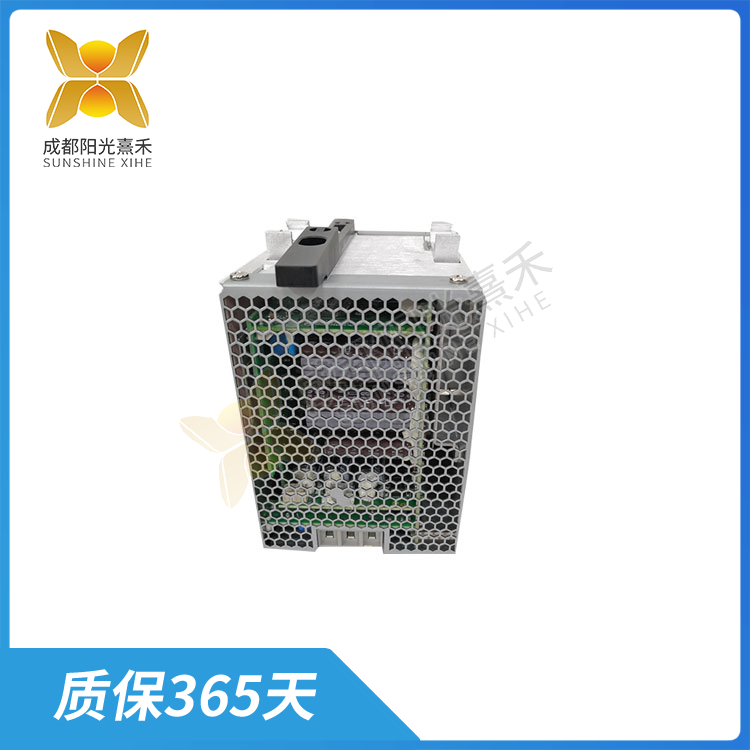

1SVR040000R1700内存卡产品介绍

本公司销售大型进口各种DCS系统模块备件:主营产品:DCS集散式控制系统、PLC可编程控制器、数控系统、

(CPU处理器、模块、卡件、控制器、伺服驱动、工作站、驱动器、马达、 内存卡、 电源,机器人备件等)各类工控产品

75-T651的硬度(HB15)的硬度,但是AA775-状态的硬度(HB6)要远远低于AA661-T651的硬度。在市场上经常见到某些牌号出现错位现象(如国产牌号硬铝LY12的硬度低于661-T6)就是这个原因。.无论是国产铝合金还是欧洲铝合金,只要牌号与美铝能够相对应,质量就大致相同,是吗?答:铝合金产品质量的好坏除与生产技术、工业装备水平、劳动者素质等因素息息相关外,还与以下因素有关:不同的生产标准和规范下的产品质量因其要求不同而不同。

主要业务: ABB DCS卡件

AB 5系列 PLC CPU,

Siemens 6DD,6FX,6SC,6FC,6S5系列,

Foxboro系统卡件,

Triconex系统模块,

Rexroth力士乐全系列产品,

Modicon停产模块 等各类工控产品

(施耐德) 140系列PLC,CPU

Ovation 系统模块

欢迎来电咨询!

如下是微波真空低温干燥的几大优点:常规的真空干燥设备都采用蒸汽进行加热,需要从里到外进行加热,加热速度慢需要耗费大量的煤,而微波真空干燥设备采用的是电磁波加热,无需传热媒介,直接加热到物体内部,升温速度快,1千瓦的微波能在3-5分钟内将常温下的水加热到1℃,避免了上述缺点,所以速度快、效率高、干燥周期大大缩短,能耗降低。与常规干燥技术相比可提高工效四倍以上。加热均匀由于微波加热,是从内到外对物料进行同时加热,物料的内外温差很小,不会产生常规加热中出现的内外加热不一致的状况,从而产生膨化的效果,利于粉碎,使干燥质量大大提高。

1svr040000r1700 75-T651的硬度(HB15)的硬度

1SVR040000R1700 This section describes the memory card

The company sells large imported DCS system module spare parts: Main products: DCS distributed control system, PLC programmable controller, numerical control system,

(CPU processors, modules, cards, controllers, servo drivers, workstations, drivers, motors, memory cards, power supplies, robot spare parts, etc.) All kinds of industrial control products

The hardness of 75-T651 (HB15), but the hardness of AA775-state (HB6) is much lower than the hardness of AA661-T651. In the market, it is often seen that some brands appear misalignment (such as the hardness of domestic brand duralumin LY12 is lower than 661-T6). Whether it is domestic aluminum alloy or European aluminum alloy, as long as the brand can correspond to Alcoa, the quality is roughly the same, right? A: The quality of aluminum alloy products is closely related to production technology, industrial equipment level, labor quality and other factors, but also related to the following factors: different production standards and specifications of product quality due to its different requirements.

Main business: ABB DCS card

AB 5 series PLC CPU,

Siemens 6DD, 6FX, 6SC, 6FC, 6S5 series,

Foxboro system card,

Triconex System module,

The full range of Rexroth products,

Modicon shutdown module and other industrial control products

(Schneider) 140 series PLC,CPU

Ovation system module

Welcome to inquire!

The following are the major advantages of microwave vacuum low temperature drying: Conventional vacuum drying equipment are heated by steam, which needs to be heated from inside to outside, and the heating speed is slow, which requires a lot of coal. While microwave vacuum drying equipment uses electromagnetic wave heating, which does not need heat transfer medium and is directly heated to the inside of the object, the heating speed is fast. 1 kW microwave can heat the water at normal temperature to 1 ° C within 3-5 minutes, avoiding the above shortcomings. Therefore, the speed is fast, the efficiency is high, the drying cycle is greatly shortened, and the energy consumption is reduced. More than four times higher efficiency than conventional drying technology. Due to microwave heating, the material is heated from inside to outside at the same time, and the temperature difference between the inside and outside of the material is very small, which will not produce the internal and external heating inconsistent situation in the conventional heating, resulting in the effect of swelling, which is conducive to crushing, and the drying quality is greatly improved.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: