Description

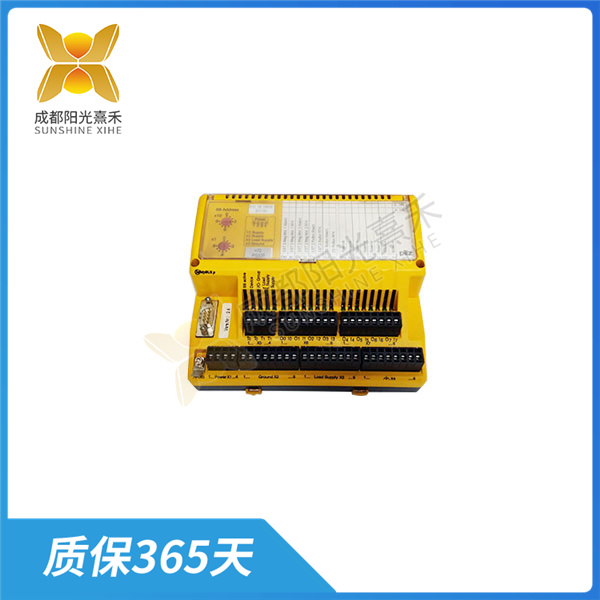

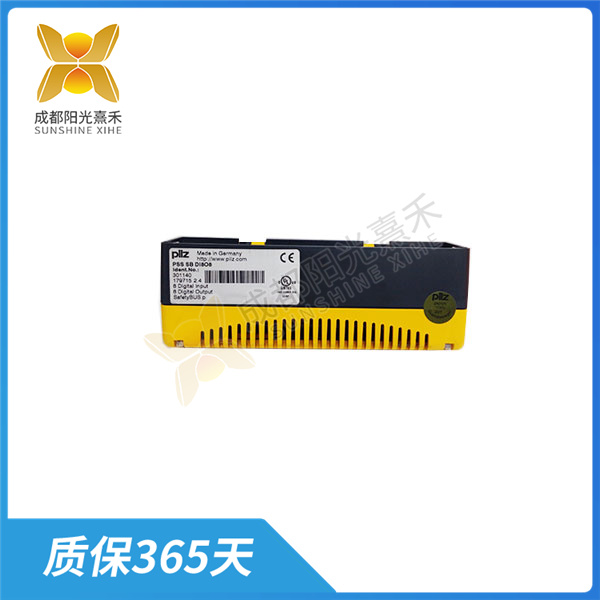

301140 用于实现特殊的功能,如PID 控制、模糊控制、运动控制等

对于PLC系统的机架式模块故障,301140可以采取以下步骤进行维修:

检查电源:确保电源供应正常,无故障。如果电源模块出现故障,需要更换相应的电源模块。

检查模块连接:检查模块之间的连接线是否完好,有无松动或断路。如果有问题,需要重新连接或更换连接线。

检查模块状态:检查机架式模块的状态指示灯是否正常,如果指示灯有故障,需要更换相应的模块。

更新软件:如果机架式模块的故障与软件相关,需要更新相应的软件或固件。

检查外部设备:如果机架式模块连接有外部设备,需要检查外部设备的状态和连接是否正常。如果有问题,需要解决外部设备的问题。

替换模块:如果以上步骤都没有解决问题,可以尝试用其他正常的机架式模块替换故障模块,以确定模块是否有问题。

在维修过程中,需要注意安全问题,避免对模块进行过度拆卸或损坏电路板等操作。同时,对于重要数据和配置信息,建议在维修前进行备份。

PLC(可编程逻辑控制器)系统的机架式模块是用于扩展 PLC 系统功能的模块化组件。301140通常安装在机架上,通过背板连接到 PLC 主机。以下是一些常见的机架式模块功能:

1. 输入模块:用于接收来自传感器、开关等输入设备的信号,并将其转换为数字信号供 PLC 处理。

2. 输出模块:用于将 PLC 处理后的数字信号转换为控制信号,输出到执行器、继电器等输出设备。

3. 通信模块:用于实现 PLC 与其他设备之间的通信,如以太网、串口、现场总线等。

4. 模拟量输入模块:用于接收模拟量信号,如温度、压力、流量等,并将其转换为数字信号供 PLC 处理。

5. 模拟量输出模块:用于将 PLC 处理后的数字信号转换为模拟量信号,输出到执行器、变频器等设备。

6. 高速计数模块:用于实现高速计数功能,如编码器计数、脉冲计数等。

7. 定位模块:用于实现定位控制功能,如步进电机控制、伺服电机控制等。

8. 特殊功能模块:用于实现特殊的功能,如PID 控制、模糊控制、运动控制等。

总之,机架式模块可以根据不同的需求进行配置和组合,301140以实现各种复杂的控制任务。它们的使用可以大大扩展 PLC 系统的功能和灵活性。

301140 用于实现特殊的功能,如PID 控制、模糊控制、运动控制等

For the PLC system rack module failure, 301140 can take the following steps to repair:

Check the power supply: Ensure that the power supply is normal. If the power module is faulty, you need to replace it.

Check module connections: Check whether the connection cables between modules are intact, loose or open. If there is a problem, you need to reconnect or replace the cable.

Module status: Check whether the status indicator of the rack module is normal. If the indicator is faulty, replace the corresponding module.

Update software: If the failure of the rack module is related to software, update the corresponding software or firmware.

Checking external devices: If a rack module is connected to an external device, check the status of the external devices and whether the connection is normal. If there is a problem, you need to solve the problem of external devices.

Replace the module: If the above steps do not solve the problem, you can try to replace the faulty module with another normal rack module to determine whether the module is faulty.

During maintenance, pay attention to safety issues and avoid excessive module disassembly or circuit board damage. In addition, you are advised to back up important data and configuration information before maintenance.

The rack-mounted module of a PLC (Programmable Logic Controller) system is a modular component used to extend the functionality of a PLC system. The 301140 is usually mounted on a rack and connected to the PLC host via a backplane. Here are some common rack-mounted module features:

1. Input module: used to receive signals from sensors, switches and other input devices, and convert them into digital signals for PLC processing.

2. Output module: It is used to convert the digital signal processed by PLC into a control signal and output to the actuator, relay and other output equipment.

3. Communication module: used to realize the communication between PLC and other devices, such as Ethernet, serial port, fieldbus, etc.

4. Analog input module: used to receive analog signals, such as temperature, pressure, flow, etc., and convert them into digital signals for PLC processing.

5. Analog output module: It is used to convert the digital signal processed by PLC into analog signal and output to the actuator, frequency converter and other equipment.

6. High-speed counting module: used to achieve high-speed counting functions, such as encoder counting, pulse counting, etc.

7. Positioning module: used to achieve positioning control functions, such as stepper motor control, servo motor control, etc.

8. Special function module: used to achieve special functions, such as PID control, fuzzy control, motion control, etc.

In short, rack-mounted modules can be configured and combined according to different needs to achieve a variety of complex control tasks. Their use can greatly expand the functionality and flexibility of the PLC system.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: