Description

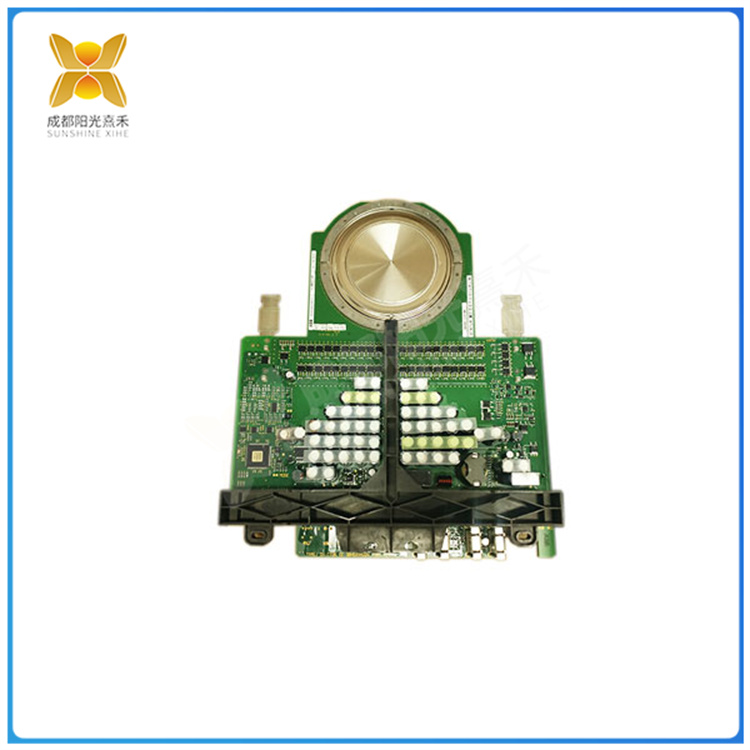

31C075-503-4-00 动态调整模型数据库结构以满足实际系统需求

PLC主要应用的领域

1.开关量逻辑控制

取代传统的继电器电路,实现逻辑控制、顺序控制,既可用于单台设备的控制,也可用于多机群控及自动化流水线。如注塑机、印刷机、订书机械、组合机床、磨床、包装生产线、电镀流水线等。

2.工业过程控制

在工业生产过程当中,存在一些如温度、压力、流量、液位和速度等连续变化的量(即模拟量),PLC采用相应的A/D和D/A转换模块及各种各样的控制算法程序来处理模拟量,完成闭环控制。PID调节是一般闭环控制系统中用得较多的一种调节方法。过程控制在冶金、化工、热处理、锅炉控制等场合有非常广泛的应用。

3.运动控制

PLC可以用于圆周运动或直线运动的控制。一般使用专用的运动控制模块,如可驱动步进电机或伺服电机的单轴或多轴位置控制模块,广泛用于各种机械、机床、机器人、电梯等场合。

4.数据处理

PLC具有数学运算(含矩阵运算、函数运算、逻辑运算)、数据传送、数据转换、排序、查表、位操作等功能,可以完成数据的采集、分析及处理。数据处理一般用于如造纸、冶金、食品工业中的一些大型控制系统。

5.通信及联网

PLC通信含PLC间的通信及PLC与其它智能设备间的通信。随着工厂自动化网络的发展,现在的PLC都具有通信接口,通信非常方便。

◆测试系统概述:

本系统主要针对各种工业、民用设备和系统的部件 (包括控制器、传感器和执行器等)进行功能和性能 测试,采用系统仿真技术实现设备和系统中与被测部件 相关的其他部件的仿真与模拟功能,从而实现被测部件的运行环境仿真测试。

运行环境仿真系统的开发首先集中于仿真模型,精确建立一个针对机电部件和系统的动态案例仿真模型库。

这个模型库有三个优点:

·基于案例推理技术的仿真模型分类结构:它可以 动态调整模型数据库结构以满足实际系统需求。

·测试仿真模型和真实系统匹配度的功能

·系统辩识工具:可以从实际的实验结果中提取精 确模型,并重构动态模型库。

这些优点可以有效地解决以前静态模型库带给仿真实验的问题。动态仿真模型库具有动态和自适应能力, 可以满足更广泛的需求。运行环境仿真系统以虚拟仪器 技术为基础的硬件在环测试系统,这使仿真变得更加容易。

31C075-503-4-00 动态调整模型数据库结构以满足实际系统需求

The main application areas of PLC

1. Switch quantity logic control

Instead of the traditional relay circuit, it can realize logic control and sequence control, which can be used for the control of a single device, and can also be used for multi-machine group control and automatic pipeline. Such as injection molding machines, printing presses, stapler machines, combined machine tools, grinding machines, packaging production lines, electroplating lines, etc.

2. Industrial process control

In the industrial production process, there are some continuous changes such as temperature, pressure, flow, liquid level and speed (that is, the analog amount), PLC uses the corresponding A/D and D/A conversion modules and a variety of control algorithms to deal with the analog amount, complete closed-loop control. PID regulation is a kind of regulation method used in general closed-loop control system. Process control is widely used in metallurgy, chemical industry, heat treatment, boiler control and so on.

3. Motion control

PLC can be used to control circular or linear motion. Generally use special motion control modules, such as single-axis or multi-axis position control modules that can drive stepper motors or servo motors, widely used in various machinery, machine tools, robots, elevators and other occasions.

4. Data processing

PLC has mathematical operations (including matrix operations, function operations, logical operations), data transmission, data conversion, sorting, table lookup, bit operation and other functions, can complete the data collection, analysis and processing. Data processing is generally used in some large control systems in the paper, metallurgy, and food industries.

5. Communication and networking

PLC communication includes communication between PLC and communication between PLC and other intelligent devices. With the development of factory automation network, PLC now has a communication interface, communication is very convenient.

◆ Test system overview:

The system mainly tests the functions and performance of various industrial and civil equipment and system components (including controllers, sensors and actuators, etc.), and adopts system simulation technology to realize the simulation and simulation functions of other components related to the components under test in the equipment and system, so as to realize the simulation test of the operating environment of the components under test.

The development of the operating environment simulation system first focuses on the simulation model, and precisely establishes a dynamic case simulation model base for electromechanical components and systems.

This model library has three advantages:

Simulation model classification structure based on case-based reasoning technology: it can dynamically adjust the model database structure to meet the actual system requirements.

· Function of testing the match between simulation model and real system

· System identification tools: accurate models can be extracted from actual experimental results and dynamic model libraries can be reconstructed.

These advantages can effectively solve the problems brought by static model library to simulation experiments. The dynamic simulation model library has dynamic and adaptive capabilities to meet a wider range of needs. The operating environment simulation system is a hardware-in-the-loop test system based on virtual instrument technology, which makes the simulation easier.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: