Description

531X305NTBANG1 专炉控制系统面置

专炉控制系统面置:每座转炉本体,散状加料,余热银炉、烟气净化各用1台PLC及操作站,转炉本体公用部分、鼓风机房、煤气回收输雷各用1台PLC及1台操作站。1#、2#转炉各设1台服务器。转炉控制系统配置。

控制系统联接网络共有四层: 1,设备网(DeviceNet/ProfiBUS) ; 2.控制网(余ontrolNet) : 3厂级管理网(EtherNet/P) ; 4.局城网(EtherNet/IP),该网设置于转炉主控室,以便转炉主控室2座转炉的10台操作站和服务器的联网使用。现场设备联接的设备网有DeviceNet、ProfiBus,如氧枪变频器、煤气鼓风机6KV中压变频器直接通过设备网卡与PLC通讯.所有1#/2#转炉及公用部分PLC、操作站、服务器之间采用(ControlNet) 几余控制网连为一休,实现PLC、操作站、服务器数据共享、实时交换车铸机、精炼炉同转一样,采用独立的ContrlLoix控制系统。厂级管理网(EtherNet/P) 将转、连铸机、LF精炉控制系统的服务器与级管理机、调度机相连接,实现主要生产、能源数据相互交换,为厂级管理和调度人员提供产生调度、决策数据.转炉各操作站、服务器采用DELL中高端配置商用计算机。服务器、操作站系统平台为Windows2000(服务器/客户版),操作站上位监控软件为RSView32,PLC组态软件为RSLogix5000,网络组态软件RSLinx(ControlVet/DeviceNet)等。转炉本体操作画面,转炉在主控室分别设置一台服务器,服务器用于网络管理、用户登陆控制,生产数据的管理、报表的打印,上位管理网的通讯、专业工程师的软件开发及维护使用等。为实现ERP功能奠定基础。在生产中服务器也可作为操作站使用。

531X305NTBANG1 专炉控制系统面置

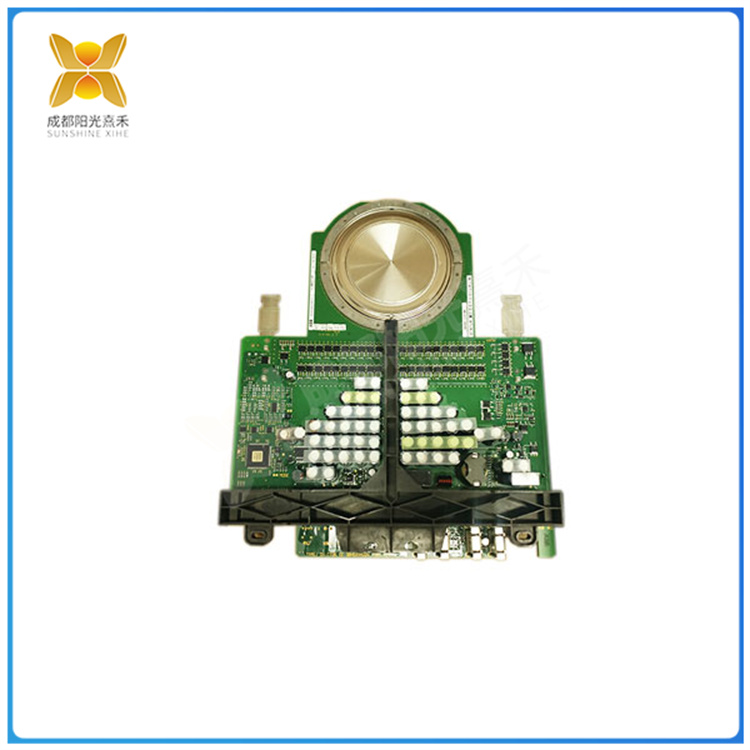

Special furnace control system: each converter body, loose feed, waste heat silver furnace, flue gas purification with 1 PLC and 1 operating station, converter body common part, blower room, gas recovery and mine transport with 1 PLC and 1 operating station. The 1# and 2# converter are each equipped with 1 server. The control system configuration of the converter is shown in FIG. 1.

The control system connection network has four layers: 1, device network (DeviceNet/ProfiBUS); 2. Control network (residual ontrolNet) : 3 factory level management network (EtherNet/P); 4. Local city network (EtherNet/IP), the network is set in the main control room of the converter, in order to network the 10 operating stations and servers of the 2 converter in the main control room of the converter. The equipment network connected to the field equipment has DeviceNet and ProfiBus, such as the oxygen gun inverter and the 6KV medium voltage inverter of the gas blower directly communicate with the PLC through the equipment network card. All 1#/2# converter and common part PLC, operation station and server use ControlNet to connect more than one control network to realize PLC, operation station and server data sharing and real-time delivery

The casting machine and refining furnace are replaced by an independent ContrlLoix control system. The plant level management network (EtherNet/P) connects the server of the converter, continuous casting machine and LF fine furnace control system with the level management machine and scheduler to realize the exchange of main production and energy data, and provides scheduling and decision data for the plant level management and scheduler. Each operation station and server of converter adopts DELL medium and high-end commercial computer. The system platform of the server and operating station is Windows2000(server/client edition), the monitoring software of the operation station is RSView32, the PLC configuration software is RSLogix5000, and the network configuration software is RSLinx(ControlVet/DeviceNet). The operation screen of the converter body is shown in Figure 2 >

The #/2# converter is equipped with a server in the main control room, which is used for network management, user login control, production data management, report printing, communication of the upper management network, software development and maintenance of professional engineers. Lay the foundation for realizing ERP function. Servers can also be used as operation stations in production.

The control system connection network has four layers: 1, device network (DeviceNet/ProfiBUS); 2. Control network (residual ontrolNet) : 3 factory level management network (EtherNet/P); 4. Local city network (EtherNet/IP), the network is set in the main control room of the converter, in order to network the 10 operating stations and servers of the 2 converter in the main control room of the converter. The equipment network connected to the field equipment has DeviceNet and ProfiBus, such as the oxygen gun inverter and the 6KV medium voltage inverter of the gas blower directly communicate with the PLC through the equipment network card. All 1#/2# converter and common part PLC, operation station and server use ControlNet to connect more than one control network to realize PLC, operation station and server data sharing and real-time delivery

The casting machine and refining furnace are replaced by an independent ContrlLoix control system. The plant level management network (EtherNet/P) connects the server of the converter, continuous casting machine and LF fine furnace control system with the level management machine and scheduler to realize the exchange of main production and energy data, and provides scheduling and decision data for the plant level management and scheduler. Each operation station and server of converter adopts DELL medium and high-end commercial computer. The system platform of the server and operating station is Windows2000(server/client edition), the monitoring software of the operation station is RSView32, the PLC configuration software is RSLogix5000, and the network configuration software is RSLinx(ControlVet/DeviceNet). The operation screen of the converter body is shown in Figure 2 >

The #/2# converter is equipped with a server in the main control room, which is used for network management, user login control, production data management, report printing, communication of the upper management network, software development and maintenance of professional engineers. Lay the foundation for realizing ERP function. Servers can also be used as operation stations in production.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址:

.jpg)