Description

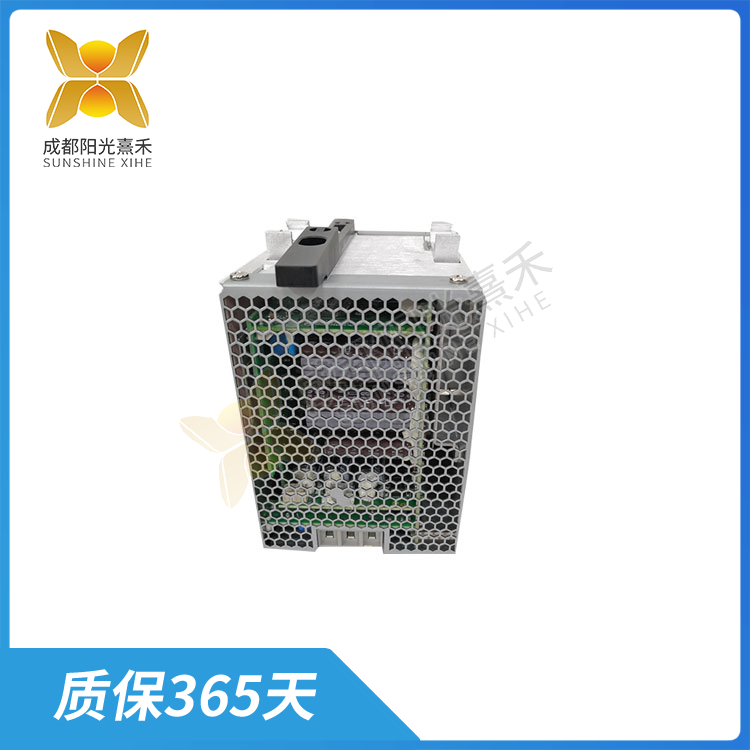

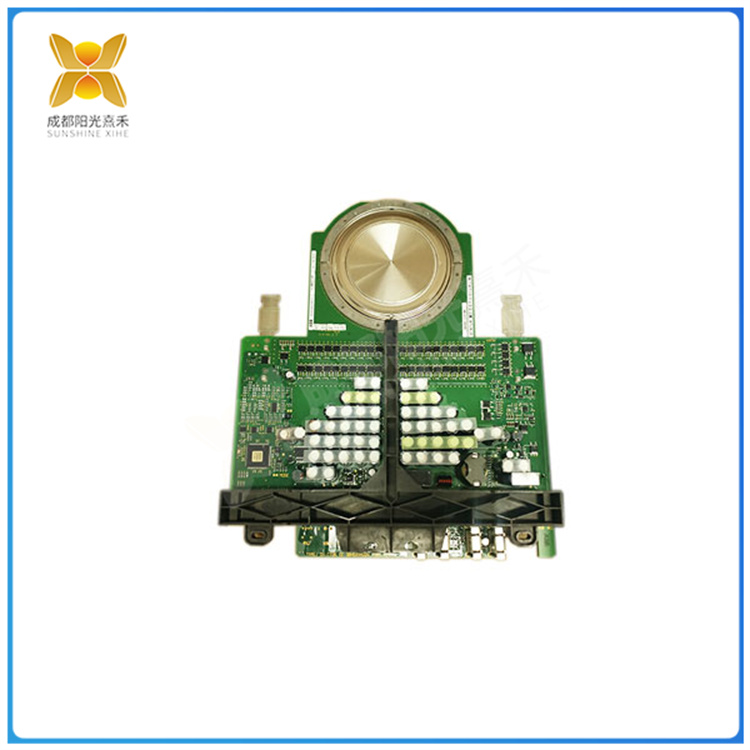

5SHY3545L0014 过程控制与通信控制西门子是强项

过程控制与通信控制西门子是强项,西门子的模拟量模块价格便宜,程序简单,而三菱的模拟量模块价格昂贵,程序复杂,西门子做通信也容易,程序简单,三菱在这块功能较弱。所以针对不同的设备不同的控制方式,我们要合理的选用PLC,用其长处,避其短处。例如某设备只是些动作控制,如机械手,可选择三菱的PLC,某设备有伺服或步进要进行定位控制,也选三菱的PLC;像中央空调,污水处理,温度控制等这类有很多模拟量要处理的就要选西门子的PLC比较合适,某设备现场有很多仪表的数据要用通信进行采集,选西门子的好控制。区别非常大的.芯片肯定是有所不同的(体现在容量和运算速度上)但最大的区别还是体现在编程软件的思路和结构上

个人认为三菱(日系的中高端品牌)PLC的软件至少落后西门子5年以上。大中型的暂且不说,就拿三菱比较有优势的小型机FX系列和西门子S7-200系列对比

1、三菱的编程软件从早期的FXGPWIN到近期的GX8.0(我所知道最新的),和所有的日系品牌一样,该软件的编程思路是自上而下的单一纵向结构,而西门子的MicroWIN则是纵向和横向兼备的结构,而且子程序支持局部变量,相同的功能只需要编一次程序即可,大大减少了开发难度和时间。

2、S7-200一直以来支持强大的浮点运算,编程软件直接支持小数点输入输出,而三菱直至近年推出的FX3U系列才有此种功能,以前的FX2N系列的浮点功能都是假的。

3、S7-200的模拟量输入输出程序非常简单方便,AD、DA值可以不需编程直接存取的,三菱的FX2N及其以前的系列都需要非常繁琐的FROMTO指令。FX3U如今倒支持此功能了,但足足晚了五年甚至更多。

4、CPU226和CPU224XP,标准配置2个485口即PPI口,最大通讯速度187.5K,三菱FX3U之前的所有系列都是一个可怜的422口,而且速度是9.6K。如果需要连个智能仪表什么的则必须另购FX2N0-485BD等特殊模块。

5、CPU226的程序容量20K,数据容量14K,FX2N总共才8K.后来的3U倒是有所改进

但三菱的FX2N系列有两个优势,一是高速计数器指令比S7-200方便。二是422口比西门子的PPI口皮实(因为200系列的PPI口是非光电隔离的,非规范操作和

仿制的编程电缆可能会导致串口损坏)西门子最近推出的S7-1200系列直接支持以太网接口,而且由于集成了计数和测量、闭环控制和运动控制的工艺,因此FX3U再次被西门子远远超越以上的比较仅仅是小型机。至于西门子的300和400系列以及更大型的TDC系列,这里就无需多言了,一句话,谁用谁知道。西门子的PCS7软件绝对是博大精深的,所有的日系品牌都只能望其项背。

学PLC,三菱是很容易上手的,因为直来直去思路简单。从学习的角度讲,肯定是西门子更好。还是那句话,用了PCS7,才知道日系的软件是垃圾。

还有西门子PLC的通信口有两个,三菱的有一个,两个通信口可以一个连接下载数据线一个连接触摸屏进行调试程序,否则你就要拔下触摸屏数据线再连接触摸屏数据线来回调整程序非常麻烦。

5SHY3545L0014 过程控制与通信控制西门子是强项

Process control and communication control Siemens is the strong point, Siemens analog module is cheap, the program is simple, and Mitsubishi analog module is expensive, the program is complex, Siemens communication is also easy, the program is simple, Mitsubishi is weak in this function. Therefore, for different equipment and different control methods, we should reasonably choose PLC, use its strengths and avoid its weaknesses. For example, a device is only some action control, such as a manipulator, you can choose Mitsubishi PLC, a device has servo or step to position control, you can also choose Mitsubishi PLC; Like central air conditioning, sewage treatment, temperature control and so on, there are a lot of analog quantities to deal with, it is more appropriate to choose Siemens PLC, a lot of instrument data on the site to be collected by communication, choose Siemens good control. The chips are definitely different (in terms of capacity and speed) but the biggest difference is in the way the software is programmed and structured

I personally believe that the software of Mitsubishi PLC is at least 5 years behind that of Siemens. Large and medium-sized for the time being, take the advantage of Mitsubishi’s minicompanies FX series and Siemens S7-200 series contrast

1. Mitsubishi’s programming software from the early FXGPWIN to the recent GX8.0(the latest one I know), like all Japanese brands, the programming idea of this software is a top-down single vertical structure, while Siemens’ MicroWIN is both vertical and horizontal structure, and the subroutine supports local variables. The same function only needs to be programmed once, which greatly reduces the difficulty and time of development.

2, S7-200 has always supported a strong floating point operation, programming software directly supports the decimal point input and output, and Mitsubishi until the FX3U series launched in recent years to have this function, the floating point function of the previous FX2N series is fake.

3, the S7-200 analog input and output program is very simple and convenient, AD, DA values can be directly accessed without programming, Mitsubishi FX2N and its previous series require very cumbersome FROMTO instructions. FX3U now supports this feature, but five years or more later.

4, CPU226 and CPU224XP, the standard configuration of two 485 ports that is PPI port, the maximum communication speed of 187.5K, Mitsubishi FX3U before all series are a poor 422 ports, and the speed is 9.6K. If you need to connect a smart instrument, you must buy special modules such as FX2N0-485BD.

5, CPU226 program capacity 20K, data capacity 14K,FX2N a total of 8K. The later 3U was an improvement

But Mitsubishi’s FX2N series has two advantages, one is that the high-speed counter instruction is more convenient than the S7-200. The second is 422 more than the Siemens PPI mouth (because the 200 series PPI mouth is non-photoelectric isolation, non-standard operation and

The recently introduced S7-1200 series from Siemens directly supports Ethernet interfaces, and thanks to the integration of counting and measurement, closed-loop control, and motion control processes, the FX3U is once again far exceeded by Siemens by the above comparison of just minicommitters. As for the Siemens 300 and 400 series and the larger TDC series, there is no need to say more here, in a word, who uses who knows. Siemens’ PCS7 software is absolutely extensive and profound, and all Japanese brands can only look behind it.

Learning PLC, Mitsubishi is very easy to get started, because straight thinking is simple. From a learning point of view, Siemens is definitely better. Still the same sentence, using PCS7, just know that the Japanese software is junk.

There are also two communication ports of Siemens PLC, Mitsubishi has one, the two communication ports can be connected to download a data line and a touch screen to debug the program, otherwise you have to unplug the touch screen data line and then connect the touch screen data line to adjust the program is very troublesome.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: