Description

6410-024-N-N-N 电机的转速和转矩可以通过改变输入的电压或电流信号进行控制

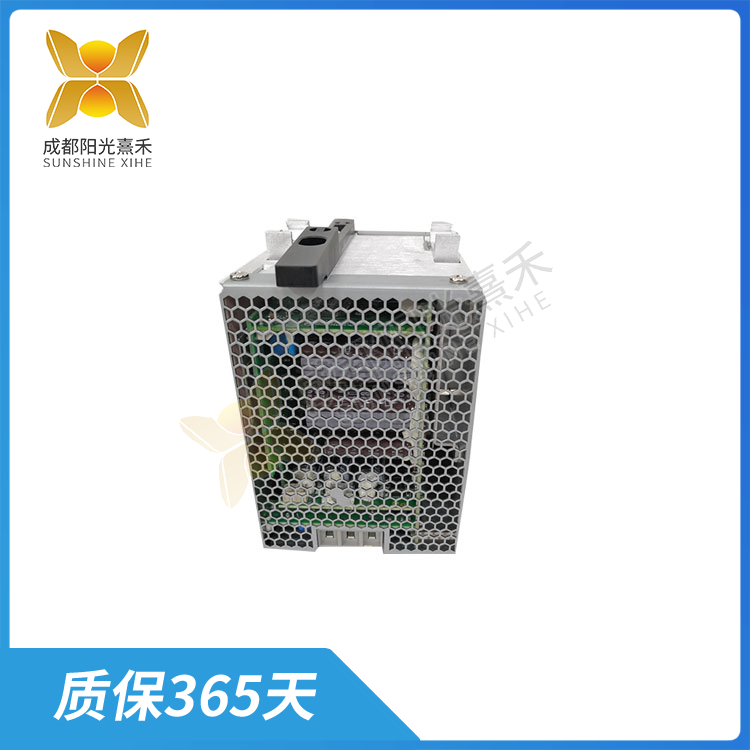

6410-024-N-N-N 异步伺服电机是一种常见的伺服系统,其伺服轴放大器轴系统是实现电机精确控制的关键部分。该系统主要包括以下几个部分:

伺服电机:作为系统的执行元件,伺服电机能够将输入的电信号转换成机械能,驱动负载进行精确的运动。电机的转速和转矩可以通过改变输入的电压或电流信号进行控制。

伺服放大器:伺服放大器是系统的核心部分,它接收来自控制系统的指令信号,并根据指令信号和电机的工作状态信号对伺服电机进行控制。放大器通常采用闭环控制方式,通过比较实际输出与指令信号的差值来调整电机的输入电压或电流,使电机的输出与指令值保持一致。

反馈装置:为了实现精确的控制,需要将电机的输出信号反馈给控制系统。反馈装置通常包括速度传感器和位置传感器等,它们可以将电机的实际转速和位置转换成电信号,供控制系统进行比较和调整。

控制系统:控制系统是整个伺服系统的指挥中心,它根据指令信号和反馈信号对伺服电机进行控制。控制系统的核心是控制器,它可以是数字控制器或模拟控制器,根据控制算法对输入信号进行处理,输出驱动电机的控制信号。

异步伺服电机的伺服轴放大器轴系统的运行原理是:当控制系统发出指令后,伺服放大器接收指令并驱动伺服电机转动。电机通过联轴器等传动装置将动力传递给负载,使负载进行相应的运动。同时,反馈装置将电机的实际运动状态反馈给控制系统,控制系统根据反馈信号和指令信号的差值进行调整,使电机的输出与指令值保持一致。通过这样的闭环控制方式,实现对异步伺服电机的高精度控制。

总之,6410-024-N-N-N 异步伺服电机的伺服轴放大器轴系统是一个复杂的控制系统,它通过精确的信号处理和控制算法,实现了对伺服电机的精确控制。该系统广泛应用于各种需要高精度运动控制的场合,如数控机床、机器人、自动化生产线等。

6410-024-N-N-N 电机的转速和转矩可以通过改变输入的电压或电流信号进行控制

6410-024-N-N-N asynchronous servo motor is a common servo system, and its servo axis amplifier axis system is a key part of achieving accurate motor control. The system mainly includes the following parts:

Servo motor: As the executive element of the system, the servo motor can convert the input electrical signal into mechanical energy to drive the load for precise movement. The speed and torque of the motor can be controlled by changing the input voltage or current signal.

Servo amplifier: The servo amplifier is the core part of the system, it receives the command signal from the control system, and controls the servo motor according to the command signal and the working state signal of the motor. The amplifier usually adopts a closed-loop control mode to adjust the input voltage or current of the motor by comparing the difference between the actual output and the command signal, so that the output of the motor is consistent with the command value.

Feedback device: In order to achieve accurate control, the output signal of the motor needs to be fed back to the control system. Feedback devices usually include speed sensors and position sensors, which can convert the actual speed and position of the motor into electrical signals for comparison and adjustment by the control system.

Control system: The control system is the command center of the whole servo system, which controls the servo motor according to the command signal and feedback signal. The core of the control system is the controller, which can be a digital controller or an analog controller, which processes the input signal according to the control algorithm and outputs the control signal that drives the motor.

The operation principle of the servo amplifier axis system of the asynchronous servo motor is that when the control system issues an instruction, the servo amplifier receives the instruction and drives the servo motor to rotate. The motor transmits power to the load through a transmission device such as a coupling, so that the load moves accordingly. At the same time, the feedback device feedbacks the actual motion state of the motor to the control system, and the control system adjusts according to the difference between the feedback signal and the command signal, so that the output of the motor is consistent with the command value. Through this closed-loop control mode, the asynchronous servo motor can be controlled with high precision.

In short, the servo axis amplifier system of 6410-024-N-N-N asynchronous servo motor is a complex control system, which realizes the precise control of the servo motor through accurate signal processing and control algorithms. The system is widely used in various occasions requiring high precision motion control, such as CNC machine tools, robots, automatic production lines and so on.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: