Description

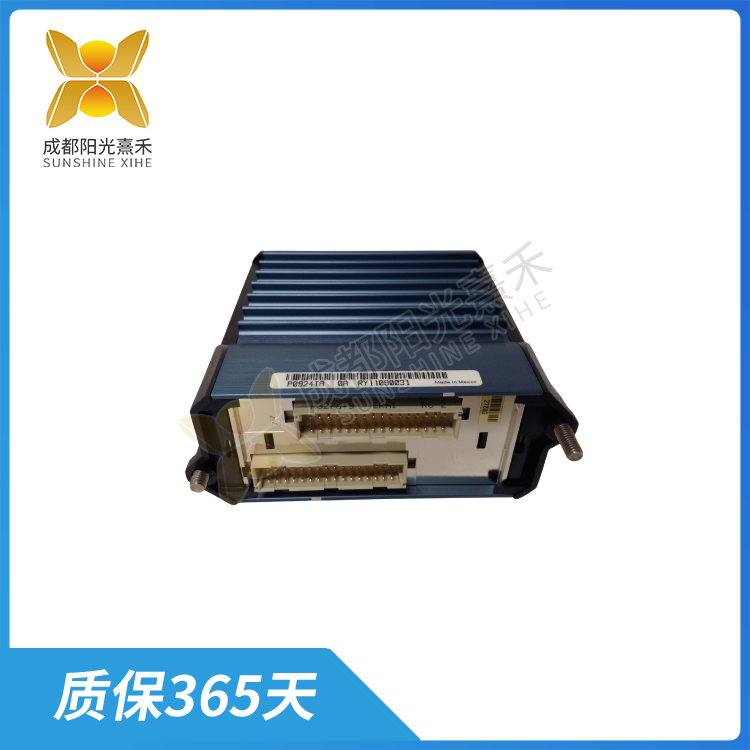

FBM201e P0924TR 模拟输入模块可以用于速度和转速的监测

在工业自动化领域,模拟输入模块的应用场景非常广泛。以下是模拟输入模块FBM201e P0924TR 在工业自动化领域的一些常见应用场景:

温度和压力监测:在工业生产过程中,温度和压力是常见的监控参数。模拟输入模块可以连接温度和压力传感器,实时监测生产过程中的温度和压力变化,并将数据传输给控制系统。

流量和液位控制:模拟输入模块可以用于监测和控制流量和液位。通过连接流量计和液位计,模块能够实时监测流量和液位的状态,并根据需要进行调整和控制。

重量和力检测:模拟输入模块可以用于重量和力的测量。在生产线上,重量和力的监测对于产品质量控制和生产安全至关重要。模拟输入模块能够将重量和力的模拟信号转换为数字信号,便于数据处理和传输。

位置和位移传感器:模拟输入模块可以连接位置和位移传感器,用于监测物体的位置和位移变化。这在自动化生产线、机器人定位和自动化门控系统中具有应用价值。

速度和转速监测:模拟输入模块可以用于速度和转速的监测。通过连接速度传感器(如光电编码器),模块能够实时监测设备或系统的速度和转速,为控制系统提供关键的反馈信息。

振动和应变监测:模拟输入模块可以用于监测设备的振动和应变情况。这对于预测性维护和设备健康监测具有重要意义,能够及时发现潜在的问题并采取相应的措施。

过程控制和监控:模拟输入模块在过程控制和监控中发挥着重要作用。它可以采集各种传感器信号,并将数据传输给控制系统,以便进行实时调整和控制。这对于化工、制药、食品加工等行业的过程控制非常关键。

总之,FBM201e P0924TR 模拟输入模块在工业自动化领域的应用非常广泛,涵盖了温度、压力、流量、重量、位置、速度等多个方面的监测和控制。通过提供准确可靠的模拟信号转换和数据处理功能,模拟输入模块为工业自动化系统的稳定运行提供了重要支持。

FBM201e P0924TR 模拟输入模块可以用于速度和转速的监测

In the field of industrial automation, analog input modules are widely used. The following are some common application scenarios of the analog input module FBM201e P0924TR in the field of industrial automation:

Temperature and pressure monitoring: In industrial production processes, temperature and pressure are common monitoring parameters. The analog input module can connect temperature and pressure sensors to monitor temperature and pressure changes in the production process in real time and transmit the data to the control system.

Flow and level control: Analog input modules can be used to monitor and control flow and level. By connecting the flow meter and the level meter, the module can monitor the status of the flow and level in real time, and adjust and control it as needed.

Weight and force detection: Analog input modules can be used for weight and force measurement. In the production line, the monitoring of weight and force is essential for product quality control and production safety. The analog input module can convert the analog signals of weight and force into digital signals for easy data processing and transmission.

Position and displacement sensors: Analog input modules can be connected to position and displacement sensors for monitoring changes in the position and displacement of objects. This has application value in automated production lines, robot positioning and automated gate control systems.

Speed and speed monitoring: Analog input modules can be used for speed and speed monitoring. By connecting speed sensors, such as photoelectric encoders, the module is able to monitor the speed and rotational speed of the device or system in real time, providing critical feedback to the control system.

Vibration and strain monitoring: Analog input modules can be used to monitor the vibration and strain of equipment. This is of great significance for predictive maintenance and equipment health monitoring to detect potential problems in time and take appropriate measures.

Process control and monitoring: Analog input modules play an important role in process control and monitoring. It can collect various sensor signals and transmit the data to the control system for real-time adjustment and control. This is critical for process control in chemical, pharmaceutical, food processing and other industries.

In short, the FBM201e P0924TR analog input module has a wide range of applications in the field of industrial automation, covering temperature, pressure, flow, weight, position, speed and other aspects of monitoring and control. By providing accurate and reliable analog signal conversion and data processing functions, analog input modules provide important support for the stable operation of industrial automation systems.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: