Description

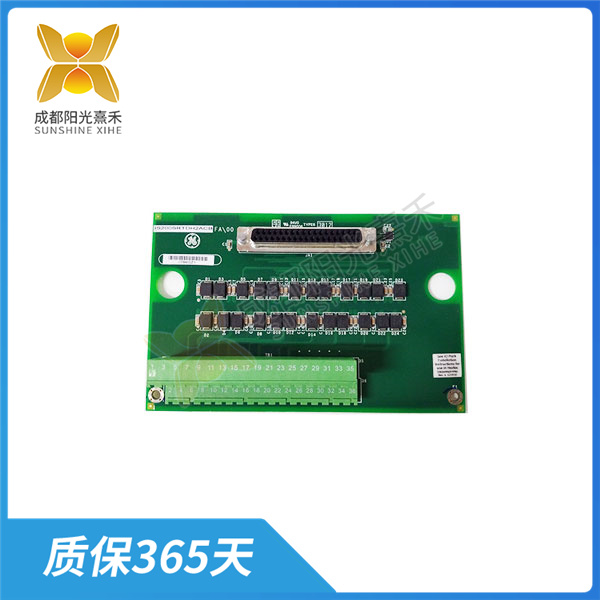

IS200SRTDH2ABB 高速通信网络实现数据的交换和控制指令的传输

Mark VI板是GE(通用电气)公司为其燃气轮机产品开发的控制系统中的一个关键组件。Mark VI板是印刷电路板,IS200SRTDH2ABB负责处理燃气轮机的各种控制功能。这些功能可能包括监控燃气轮机的运行状态、接收和响应操作员的输入指令、控制燃气轮机的启动和停止等。

Mark VI板的设计考虑了冗余性,以提高系统的可靠性。这意味着如果有任何一块Mark VI板出现故障,其他板可以接管其任务,确保燃气轮机的连续运行。此外,Mark VI板通常与触摸屏、PLC(可编程逻辑控制器)、卡件等其他设备协同工作,以实现对整个燃气轮机系统的全面控制。

Mark VI板作为GE公司燃气轮机控制系统的核心组件,还有一些其他重要信息值得了解:

模块化设计:Mark VI板采用模块化设计,这意味着它可以通过添加或删除模块来适应不同的燃气轮机配置和控制需求。这种设计提供了很大的灵活性和可扩展性,使得Mark VI系统能够适应不断变化的运行环境和操作要求。

三重冗余架构:Mark VI系统的一个显著特点是采用了三重冗余架构(TMR),这意味着系统中的关键组件(包括Mark VI板)都有三个独立的实例在运行。如果一个实例出现故障,其他两个实例可以继续工作,确保系统不会中断运行。这种设计提供了非常高的可靠性和可用性。

基于PC的HMI:Mark VI系统还包括一个基于PC的人机界面(HMI),操作员可以通过这个界面监控燃气轮机的运行状态、输入控制指令,并查看相关的报警和诊断信息。这个HMI界面通常是触摸屏形式,使得操作更加直观和便捷。

集成与通信:Mark VI板与其他控制系统组件(如PLC、传感器、执行器等)进行集成,通过高速通信网络实现数据的交换和控制指令的传输。这使得整个控制系统能够作为一个协调一致的整体来工作,确保燃气轮机的安全、高效运行。

软件配置与更新:Mark VI板的控制功能是通过软件来实现的,这意味着可以通过软件配置和更新来改变系统的行为或添加新的控制策略。这为用户提供了很大的灵活性,可以根据需要进行定制化的控制方案。

维护与故障排除:虽然Mark VI板经过严格的质量控制和测试,但在长期运行过程中仍可能出现故障。对于这种情况,GE公司提供了相应的维护手册和故障排除指南,以帮助用户快速定位和解决问题。

总的来说,Mark VI板IS200SRTDH2ABB 作为GE燃气轮机控制系统的核心组件,具有高度的可靠性、灵活性和可扩展性。通过了解其设计特点、功能和应用范围,用户可以更好地使用和维护这个系统,确保燃气轮机的稳定运行和性能优化。

IS200SRTDH2ABB 高速通信网络实现数据的交换和控制指令的传输

The Mark VI board is a key component in the control system developed by GE for its gas turbine products. The Mark VI board is a printed circuit board, and the IS200SRTDH2ABB handles the various control functions of the gas turbine. These functions may include monitoring the operating status of the gas turbine, receiving and responding to operator input commands, and controlling the start and stop of the gas turbine.

Mark VI boards are designed with redundancy in mind to improve system reliability. This means that if any of the Mark VI boards fails, the others can take over their tasks and ensure continuous operation of the gas turbine. In addition, the Mark VI board usually works in conjunction with other devices such as touch screens, PLC (programmable logic controller), clamp pieces, etc., to achieve complete control of the entire gas turbine system.

As the core component of GE’s gas turbine control system, the Mark VI board has some other important information to know:

Modular design: The Mark VI board has a modular design, which means that it can be adapted to different gas turbine configuration and control needs by adding or removing modules. This design provides a great deal of flexibility and scalability, allowing the Mark VI system to adapt to changing operating environments and operational requirements.

Triple Redundant Architecture: A distinguishing feature of the Mark VI system is the triple redundant architecture (TMR), which means that the key components of the system, including the Mark VI board, have three separate instances running. If one instance fails, the other two instances can continue to work, ensuring that the system does not interrupt operation. This design provides very high reliability and availability.

Pc-based HMI: The Mark VI system also includes a PC-based Human Machine interface (HMI) through which the operator can monitor the operating status of the gas turbine, enter control commands, and view relevant alarm and diagnostic information. This HMI interface is usually in the form of a touch screen, making operation more intuitive and convenient.

Integration and communication: The Mark VI board is integrated with other control system components (such as PLCS, sensors, actuators, etc.) to realize the exchange of data and the transmission of control instructions through high-speed communication networks. This allows the entire control system to work as a coherent whole, ensuring safe and efficient operation of the gas turbine.

Software configuration and update: The control function of the Mark VI board is implemented through software, which means that the software can be configured and updated to change the behavior of the system or add new control policies. This gives the user a lot of flexibility to tailor the control scheme as needed.

Maintenance and Troubleshooting: Although the Mark VI board has undergone strict quality control and testing, it can still fail during long-term operation. In this case, GE provides maintenance manuals and troubleshooting guides to help you quickly locate and rectify the problem.

Overall, the Mark VI board IS200SRTDH2ABB is the core component of GE’s gas turbine control system, offering a high degree of reliability, flexibility and scalability. By understanding its design features, functions and application range, users can better use and maintain the system to ensure stable operation and performance optimization of the gas turbine.

| sr469 – p1 – hi – a20 – ege469电机管理继电器 | G408-0001 ULTRA SLIMPAK®直流供电直流输入场可配置隔离器 |

| 8202-HO-IS GE 8通道是AO, 4-20 mA与哈特 | VMIACC-0584 GE CompactPCI®单板计算机 |

| SR469继电器 | ADTRON模拟输入模块 |

| XPSMC32ZP施耐德安全控制器 | RMP200-8远程多用途输入输出康士伯 |

| DDC779BE102 3BHE006805R0002以太网控制模块ABB | ACC-24E2轴扩展板Delta Tau |

| NI-9263 NI C系列电压输出模块 | UAC389AE02 ABB模拟输入模块 |

| YOKOGAWA程序控制器UP55A | ADTRON模拟输入模块 |

| 8201-HI-IS GE 8通道IS AI, 4-20mA带Hart | CB6687-2L PILLAR模拟输入模块 |

| TCSESM043F2CS0 Schneider以太网TCP/IP管理交换机 | SPAU140C ABB同步检查继电器 |

| 1336F-BRF50-AA-EN-HAS2艾伦-布拉德利可调频率驱动器制造 | 横河控制系统ANB10D-420/CU2N/NDEL |

| 1336-BDB-SP11C Allen-Bradley栅极驱动器PCB制造 | 192061B-02多功能电缆NI |

| SR469-P5-HI-A20-H GE电机管理继电器 | 太平洋科学步进驱动器 |

| 140NRP31200C Schneider以太网光纤转换器 | 霍尼韦尔单通道控制卡催化 |

| TC-PPD011 Honeywell电池扩展模块 | 霍尼韦尔单通道控制卡催化 |

| TK-FPDXX2霍尼韦尔电池扩展模块 | 步进电机太平洋科学公司 |

| 369-HI-0-M-F-E-0 GE电机管理继电器 | TS2640N321E64 TAMAGAWA无刷变压器 |

| PPD513 A24-110110静态励磁系统ABB | 05704-A-0122 HONEYWELL高性能压力传感器 |

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: