Description

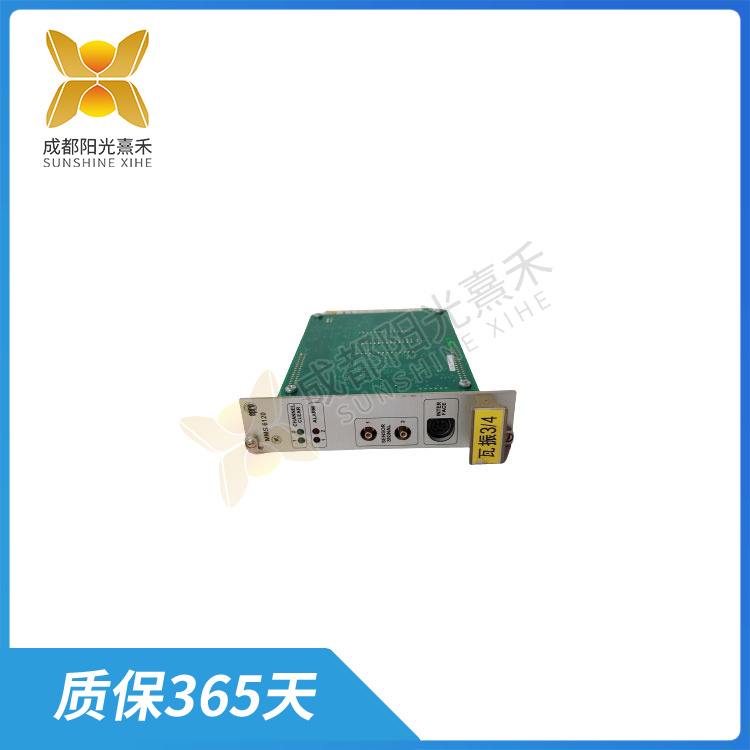

MMS6120-9100-00002C-08 双通道轴承振动监视器广泛应用于各种旋转机械设备的状态监测和故障诊断

双通道轴承振动监视器在许多工业领域中都有广泛的应用,以下是MMS6120-9100-00002C-08 常见的应用场景:

旋转机械设备:双通道轴承振动监视器广泛应用于各种旋转机械设备的状态监测和故障诊断,如电机、涡轮机、压缩机、泵等。通过实时监测轴承的振动情况,可以及时发现潜在的故障和异常,避免设备损坏和生产事故的发生。

轴承制造与装配过程监控:在轴承的制造和装配过程中,双通道轴承振动监视器可以用于监测轴承的质量和装配精度。通过测量轴承的振动数据,可以评估其加工精度和装配质量,确保产品的合格性和稳定性。

重型装备与运输设备:对于一些重型装备和运输设备,如火车、地铁车辆、船舶等,轴承振动监视器可以用于监测轴承的工作状态和磨损情况。这些设备的轴承工作环境较为恶劣,容易出现磨损和故障,通过实时监测和预警系统可以及时发现潜在问题并采取相应措施。

风力发电领域:在风力发电领域,双通道轴承振动监视器可以用于监测风力发电机轴承的工作状态。风力发电机的工作环境复杂多变,轴承是其中一个关键部件,通过实时监测其振动数据,可以及时发现潜在的故障和异常,确保风力发电机的正常运行。

总的来说,双通道轴承振动监视器的应用范围非常广泛,MMS6120-9100-00002C-08 可以应用于各种需要监测轴承振动情况的生产设备中。通过对轴承的实时监测和预警系统,可以提高设备的可靠性和安全性,减少设备的维护和维修成本,为企业带来更多的经济效益。

MMS6120-9100-00002C-08 双通道轴承振动监视器广泛应用于各种旋转机械设备的状态监测和故障诊断

Dual-channel bearing vibration monitor has a wide range of applications in many industrial fields, the following are the common application scenarios of MMS6120-9100-00002C-08:

Rotating machinery equipment: two-channel bearing vibration monitor is widely used in various rotating machinery equipment condition monitoring and fault diagnosis, such as motors, turbines, compressors, pumps, etc. Through real-time monitoring of bearing vibration, potential faults and anomalies can be found in time to avoid equipment damage and production accidents.

Bearing manufacturing and assembly process monitoring: During the manufacturing and assembly of bearings, the two-channel bearing vibration monitor can be used to monitor the quality and assembly accuracy of bearings. By measuring the vibration data of the bearing, its processing accuracy and assembly quality can be assessed to ensure the conformity and stability of the product.

Heavy equipment and transportation equipment: For some heavy equipment and transportation equipment, such as trains, subway vehicles, ships, etc., bearing vibration monitors can be used to monitor the working condition and wear of bearings. The bearing working environment of these equipment is harsh and prone to wear and failure, and potential problems can be found in time and corresponding measures can be taken through real-time monitoring and early warning system.

Wind power field: In the field of wind power generation, dual-channel bearing vibration monitors can be used to monitor the working status of wind turbine bearings. The working environment of the wind turbine is complex and changeable, and the bearing is one of the key components. Through real-time monitoring of its vibration data, potential faults and anomalies can be found in time to ensure the normal operation of the wind turbine.

In general, the dual-channel bearing vibration monitor has a very wide range of applications, and MMS6120-9100-00002C-08 can be applied to a variety of production equipment that needs to monitor bearing vibration. Through the real-time monitoring and early warning system of bearings, the reliability and safety of equipment can be improved, the maintenance and repair costs of equipment can be reduced, and more economic benefits can be brought to enterprises.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: