Description

S20330-SRS 伺服驱动器将这些脉冲信号转换为电机的控制信号

伺服驱动器的工作原理主要是通过接收来自控制器的脉冲信号,驱动电机转动,从而实现对机械设备的精确控制。

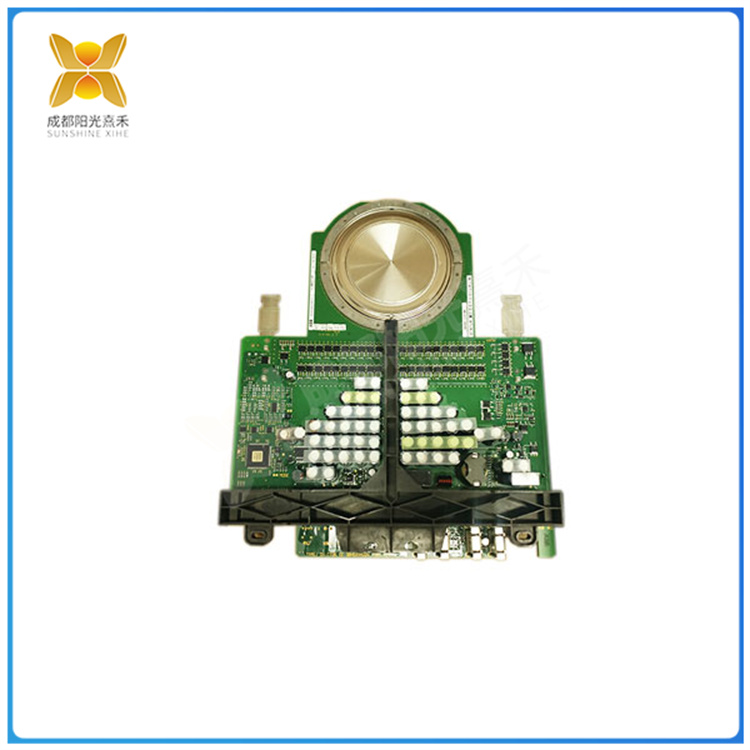

具体来说,S20330-SRS伺服驱动器首先接收来自控制器的脉冲信号,这些脉冲信号包含了电机的转动方向和速度等信息。然后,伺服驱动器将这些脉冲信号转换为电机的控制信号,通过驱动电机内部的电子换向器,控制电机的电流和电压,从而驱动电机转动。

在电机转动的过程中,S20330-SRS伺服驱动器还会通过编码器等传感器实时监测电机的位置和速度等信息,并将这些信息反馈给控制器。控制器根据这些反馈信息调整脉冲信号的频率和幅度,从而实现对机械设备的精确控制。

此外,伺服驱动器还具有一些其他的控制功能,如速度控制、转矩控制等。这些功能可以通过控制器发送的特定信号实现。例如,通过发送速度控制信号,伺服驱动器可以控制电机以指定的速度转动;通过发送转矩控制信号,伺服驱动器可以控制电机以指定的转矩输出。

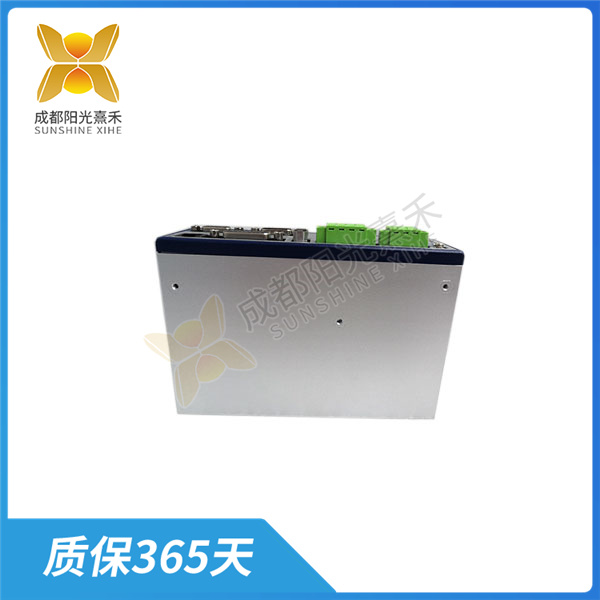

伺服驱动器又称为“伺服控制器”、“伺服放大器”,是用来控制伺服电机的一种控制器,属于伺服系统的一部分,主要应用于高精度的定位系统。

伺服驱动器一般通过位置、速度和力矩三种方式对伺服马达进行控制,实现高精度的传动系统定位,是传动技术的高端产品。

伺服驱动器的工作原理:首先功率驱动单元通过三相全桥整流电路对输入的三相电或者市电进行整流,得到相应的直流电。 经过整流好的三相电或市电,再通过三相正弦PWM电压型逆变器变频来驱动交流伺服电机。 功率驱动单元的整个过程可以简单的说就是AC-DC-AC的过程,整流单元(AC-DC)主要的拓扑电路是三相全桥不控整流电路。

总之,S20330-SRS伺服驱动器的工作原理是通过接收并解析来自控制器的脉冲信号,驱动电机转动,同时通过传感器反馈电机的位置和速度等信息给控制器,从而实现对机械设备的精确控制。

S20330-SRS 伺服驱动器将这些脉冲信号转换为电机的控制信号

The working principle of the servo driver is mainly to drive the motor to rotate by receiving the pulse signal from the controller, so as to realize the precise control of the mechanical equipment.

Specifically, the S20330-SRS servo driver first receives pulse signals from the controller, which contain information such as the direction and speed of the motor rotation. Then, the servo driver converts these pulse signals into the control signal of the motor, and controls the current and voltage of the motor by driving the electronic commutator inside the motor, thereby driving the motor to rotate.

In the process of motor rotation, the S20330-SRS servo drive will also monitor the position and speed of the motor through sensors such as encoders in real time, and feed this information to the controller. According to these feedback information, the controller adjusts the frequency and amplitude of the pulse signal, so as to achieve accurate control of the mechanical equipment.

In addition, the servo drive also has some other control functions, such as speed control, torque control and so on. These functions can be implemented through specific signals sent by the controller. For example, by sending a speed control signal, the servo drive can control the motor to rotate at a specified speed; By sending a torque control signal, the servo drive can control the motor to a specified torque output.

Servo driver, also known as “servo controller” and “servo amplifier”, is a controller used to control the servo motor, which is a part of the servo system, mainly used in high-precision positioning system.

Servo drive generally through the position, speed and torque three ways to control the servo motor, to achieve high-precision transmission system positioning, is a high-end product of transmission technology.

The working principle of the servo driver: First, the power drive unit through the three-phase full bridge rectifier circuit to the input three-phase or mains rectified, to obtain the corresponding direct current. The AC servo motor is driven by a three-phase sinusoidal PWM voltage inverter after good rectification or mains power. The whole process of the power drive unit can be simply said to be the process of AC-DC-AC, and the main topological circuit of the rectifier unit (AC-DC) is a three-phase full-bridge uncontrolled rectifier circuit.

In short, the working principle of the S20330-SRS servo driver is to drive the motor by receiving and analyzing the pulse signal from the controller, and at the same time feedback the position and speed of the motor through the sensor to the controller, so as to achieve accurate control of the mechanical equipment.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: