Description

S21260-SRS 处理后的控制信号转换为电机驱动所需的电压和电流,从而驱动电机转动

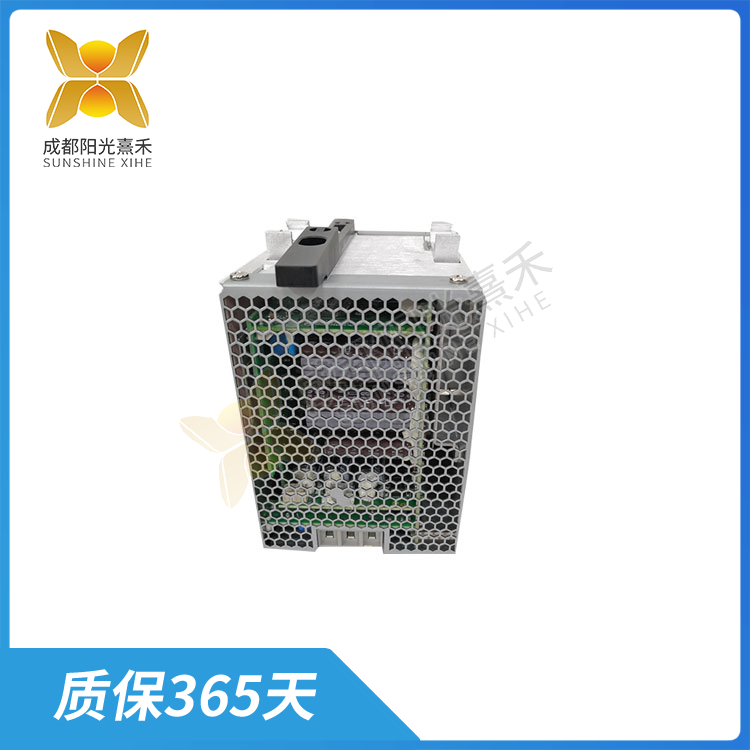

伺服驱动器模块是伺服驱动器的核心组成部分,S21260-SRS伺服驱动器控制模块通常需要高带宽电流环路实现平滑的扭矩和速度/位置控制,通过低延迟、低位错误、抗EMC干扰的接口连接到编码器、现场总线/以太网,通过高性能信号链处理来自编码器/旋转变压器的正弦/余弦信号,以及高效、有序和受控的电压轨,用于实现可靠运行。

伺服驱动器模块的工作原理主要包括以下几个方面:

信号接收与处理:S21260-SRS伺服驱动器模块首先接收来自控制器的控制信号,这些信号通常包含电机的转动方向、速度等指令。然后,驱动器对这些信号进行解析和处理,以确定电机的具体运动参数。

电机驱动:伺服驱动器模块通过驱动电路对电机进行驱动。这个过程通常包括将处理后的控制信号转换为电机驱动所需的电压和电流,从而驱动电机转动。

位置与速度反馈:S21260-SRS在电机转动过程中,伺服驱动器模块会通过编码器等传感器实时监测电机的位置和速度。这些信息会被反馈给控制器,形成闭环控制。

故障检测与保护:S21260-SRS伺服驱动器模块还具有故障检测和保护功能。当电机或驱动器出现故障时,驱动器会及时切断电源,防止故障扩大,同时向控制器发送故障信号,以便进行故障排除和维修。

总的来说,伺服驱动器模块的工作原理是通过接收并处理控制信号,驱动电机转动,同时实时监测电机的位置和速度,并将这些信息反馈给控制器,形成闭环控制。同时,它还具有故障检测和保护功能,确保系统的稳定运行。

S21260-SRS 处理后的控制信号转换为电机驱动所需的电压和电流,从而驱动电机转动

The servo driver module is the core component of the servo driver, the S21260-SRS servo driver control module usually requires a high bandwidth current loop for smooth torque and speed/position control, and connects to the encoder, fieldbus/Ethernet via low latency, low error, and EMC interference resistant interfaces. Sine/cosine signals from encoders/rotating transformers are processed through high-performance signal chains, as well as efficient, ordered and controlled voltage rails for reliable operation.

The working principle of servo driver module mainly includes the following aspects:

Signal reception and processing: The S21260-SRS servo driver module first receives the control signal from the controller, which usually contains the motor rotation direction, speed and other instructions. These signals are then analyzed and processed by the driver to determine the specific motion parameters of the motor.

Motor drive: The servo driver module drives the motor through the drive circuit. This process usually involves converting the processed control signal into the voltage and current required to drive the motor, thus driving the motor to turn.

Position and speed feedback: The S21260-SRS servo drive module monitors the position and speed of the motor in real time through sensors such as encoders during motor rotation. This information is fed back to the controller, creating a closed-loop control.

Fault detection and protection: The S21260-SRS servo drive module also has fault detection and protection functions. When the motor or driver fails, the driver will cut off the power in time to prevent the expansion of the fault, while sending a fault signal to the controller for troubleshooting and maintenance.

In general, the working principle of the servo drive module is to drive the motor by receiving and processing the control signal, while monitoring the position and speed of the motor in real time, and feeding this information to the controller to form a closed-loop control. At the same time, it also has fault detection and protection functions to ensure the stable operation of the system.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: