描述

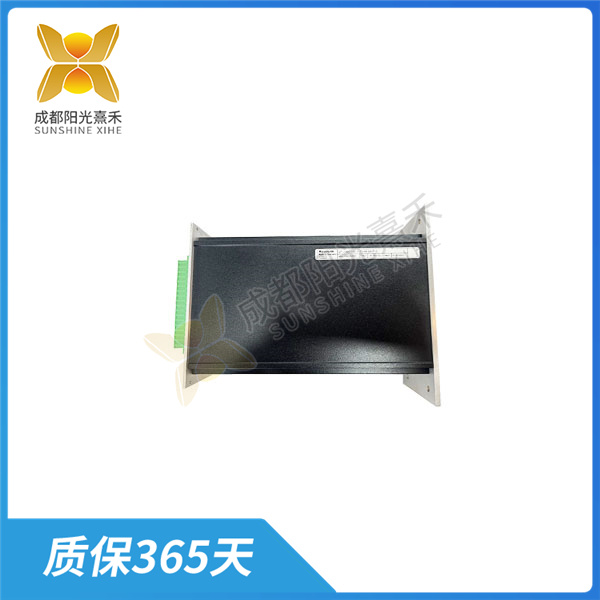

VT-HNC100-1-23W-08-P-0 符合液压驱动闭环控制的特定要求

数字轴控制器是一种可编程的NC控制器,最多可控制四个轴。VT-HNC100-1-23W-08-P-0符合液压驱动闭环控制的特定要求。数字轴控制器有VT-HNC100-1-23-W-08-0-0和VT-HNC100-2-30/N-I-00/000等型号。

数字轴控制器的工作原理基于数字信号处理器(DSP)和电力电子技术,实现对电机轴的精确控制。数字轴控制器通过将数字信号转换为模拟信号,驱动电机轴进行相应的动作。

具体来说,VT-HNC100-1-23W-08-P-0 数字轴控制器的工作原理可以分为以下几个步骤:

输入信号处理:控制器接收到来自编码器、传感器等输入设备的信号后,首先进行信号处理,包括信号放大、滤波、解码等,以提取出电机轴的位置、速度、电流等参数。

控制算法处理:控制器根据输入信号和预设的控制算法,计算出电机的控制量,如电压、电流、频率等。控制算法可以根据需要进行选择和调整,以达到不同的控制效果。

输出信号处理:控制器将计算出的控制量转换为模拟信号,输出给电机驱动器。控制信号经过D/A转换器转换成模拟信号后,驱动电机轴进行相应的动作。

反馈控制:控制器不断接收来自输入设备的反馈信号,与预设的控制目标进行比较,根据比较结果调整控制量,实现电机的闭环控制。

数字轴控制器通过以上工作原理,可以实现高精度的位置控制、速度控制和力矩控制等,广泛应用于数控机床、机器人、自动化生产线等领域。

VT-HNC100-1-23W-08-P-0 符合液压驱动闭环控制的特定要求

The digital axis controller is a programmable NC controller that can control up to four axes. The VT-HNC100-1-23W-08-P-0 meets the specific requirements of hydraulic drive closed-loop control. Digital axis controllers are available in VT-HNC100-1-23-W-08-0-0 and VT-HNC100-2-30/N-I-00/000 models.

The working principle of the digital shaft controller is based on digital signal processor (DSP) and power electronics technology to realize the precise control of the motor shaft. The digital shaft controller converts the digital signal to the analog signal and drives the motor shaft to perform the corresponding action.

Specifically, the working principle of the VT-HNC100-1-23W-08-P-0 digital axis controller can be divided into the following steps:

Input signal processing: After receiving the signal from the encoder, sensor and other input devices, the controller first carries out signal processing, including signal amplification, filtering, decoding, etc., to extract the position, speed, current and other parameters of the motor shaft.

Control algorithm processing: According to the input signal and the preset control algorithm, the controller calculates the control amount of the motor, such as voltage, current, frequency, etc. The control algorithm can be selected and adjusted according to the need to achieve different control effects.

Output signal processing: The controller converts the calculated control quantity into an analog signal and outputs it to the motor driver. After the control signal is converted into an analog signal by the D/A converter, the motor shaft is driven to perform the corresponding action.

Feedback control: The controller constantly receives feedback signals from the input device, compares them with the preset control objectives, and adjusts the control amount according to the comparison results to achieve closed-loop control of the motor.

Through the above working principle, the digital axis controller can achieve high-precision position control, speed control and torque control, etc., which is widely used in CNC machine tools, robots, automatic production lines and other fields.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: