描述

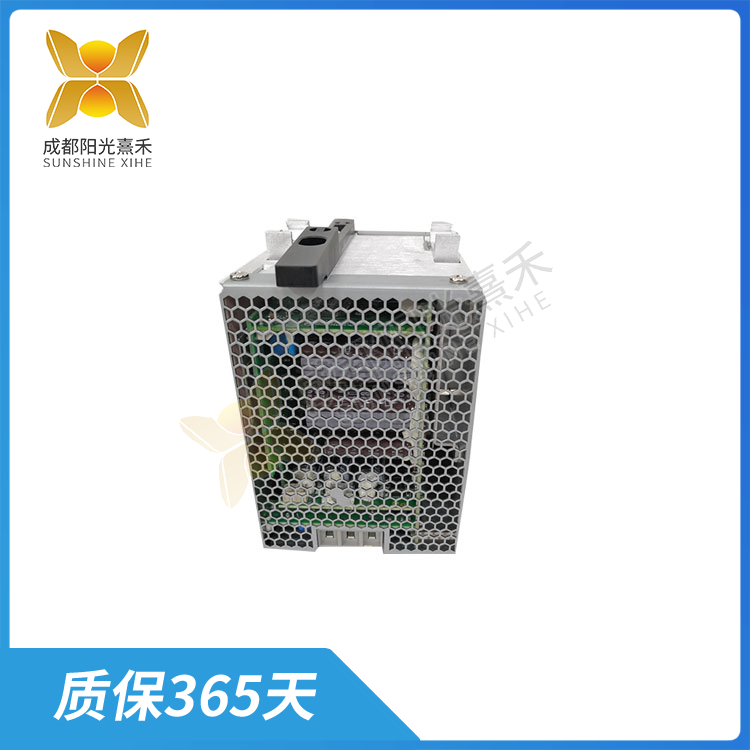

XO08R2-1SBP260109R1001 触点是继电器切换负载的电气触点部件

XO08R2-1SBP260109R1001 继电器输出扩展模块常见故障及其处理方法包括以下几点:

触点松动、开裂:触点是继电器切换负载的电气触点部件。某些产品具有通过铆接压入的触点。主要缺点是触点松动、触点有裂纹或尺寸和位置偏差过大。这会影响继电器的接触可靠性。拆卸点松动是由于簧片配合部与接触处尺寸不合理或操作人员对铆接压力调整不当造成的。接触裂纹是由过高的材料硬度或过大的压力引起的。不同材质的触头采用不同的材料,对一些硬度较高的触头材料应进行退火处理,并进行触头制造、铆接或点焊。触点制造要小心,因为材料有公差,所以每次切割的长度应在试触后确定。触点的制造不应脱掉边缘、焊盘和不丰满度。接触铆接是由于操作者接触工具未对准和上下接触未对准引起的。接触损坏和污染是由未清洁的接触工具上的油污和铁屑引起的。无论出现什么样的毛病,都会影响继电器的可靠性。因此,在触点制造、铆接或电焊过程中,必须遵循中间抽样和首件检验的Z终检验的自检划定,以提高装配质量。

继电器无电流输出:这可能是由于线圈损坏、触点接触不良或触点焊接等原因引起的。这时,可以通过检查线圈、清洁触点或更换触点来修复问题。

继电器输出异常:可能是由于触点磨损、触点松动或线圈绝缘破损等原因造成的。针对这种情况,可以更换触点、检查线圈绝缘或检查线圈绝缘来修复问题。

继电器发热:可能是由于继电器负载过大、继电器周围温度过高或线圈绝缘不良等原因引起的。针对这种情况,可以减小负载、提高通风散热或检查线圈绝缘来修复问题。

继电器输出扩展模块常见故障及其处理方法的一些方面。在实际应用中,可能还有其他故障和处理方法需要根据具体情况进行判断和处理。

XO08R2-1SBP260109R1001 触点是继电器切换负载的电气触点部件

XO08R2-1SBP260109R1001 Common faults of relay output expansion module and their solutions include the following:

Contact loosening, cracking: The contact is the electrical contact part of the relay to switch the load. Some products have contacts pressed in by riveting. The main disadvantage is that the contact is loose, the contact is cracked or the size and position deviation is too large. This affects the contact reliability of the relay. The loosening of the removal point is caused by the unreasonable size of the matching part and the contact point of the reed or the improper adjustment of the riveting pressure by the operator. Contact cracks are caused by excessive material hardness or excessive pressure. Contacts of different materials are made of different materials, and some contact materials with higher hardness should be annealed, and contact manufacturing, riveting or spot welding should be carried out. Contact manufacturing should be careful, because the material has tolerances, so the length of each cut should be determined after the test contact. Contacts should be manufactured without removing edges, pads and imperfections. Contact riveting is caused by misalignment of operator contact tools and misalignment of up and down contact. Contact damage and contamination are caused by oil and iron filings on uncleaned contact tools. No matter what kind of fault occurs, it will affect the reliability of the relay. Therefore, in the process of contact manufacturing, riveting or welding, it is necessary to follow the self-inspection demarcations of the intermediate sampling and the Z-final inspection of the first piece inspection to improve the assembly quality.

Relay no current output: This may be caused by coil damage, poor contact contact, or contact welding. At this point, the problem can be fixed by checking the coil, cleaning the contacts, or replacing the contacts.

Abnormal relay output: It may be caused by contact wear, loose contact or coil insulation damage. In this case, you can replace the contact, check the coil insulation, or check the coil insulation to fix the problem.

Relay heating: It may be caused by too much relay load, too high temperature around the relay or poor coil insulation. In this case, you can reduce the load, improve ventilation and heat dissipation, or check the coil insulation to repair the problem.

Some aspects of the common faults of relay output expansion module and their treatment methods. In actual applications, there may be other faults and troubleshooting methods that need to be identified and handled according to the actual situation.

购买咨询热线/Phone:18859254943

邮箱/Email:sales@ygdcs.com

地址:成都高新区天益街北巷52号附14号2层

购买咨询热线/Phone:

购买咨询热线/Phone: 邮箱/Email:

邮箱/Email: 地址:

地址: